Non-Invasive Ultrasound Theragnostic System

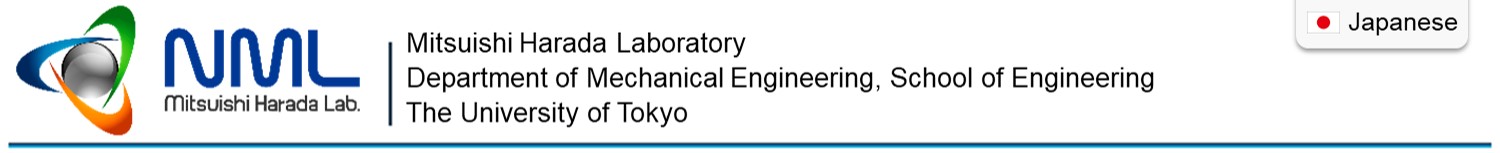

An ultrasound-image-guided therapeutic HIFU (High-Intensity Focused Ultrasound) system for renal diseases has been developed. The HIFU system is equipped with robotic servoing capability so as to track quasi-periodically moving renal tumors and stones. The developed system is composed of a US imaging unit, software for target detection, a robotic unit for servoing the end-effecter, HIFU irradiation control for destroying stones or tumors, and a quality assurance system for planning and maintaining HIFU irradiations.

|

|

Cutting Tools for Biocompatible Bone-Cutting

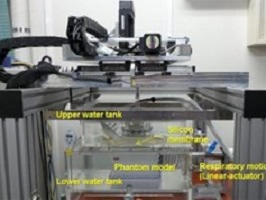

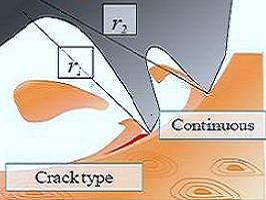

In arthroplasty, efficient and accurate bone-cutting needs to be achieved while maintaining a low cutting temperature. We have been developing biocompatible bone-cutting methods and dedicated cutting tools in order to simultaneously satisfy the requirements. More specifically, we have developed the control of crack propagation based on knowledge obtained by observing micro-nano phenomena in bone cutting. We have also developed a bone-cutting endmill with edges of different design; a edge with smaller radius is used for rough processing while a edge with larger radius is for finishing.

|

|

Tool Surface Functionalization Using Micro-Fabrication Technology

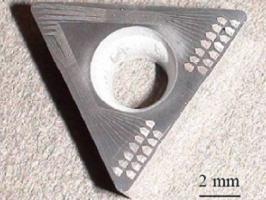

We have developed a new cutting tool with temperature sensing capability for continuous in-process measurement of cutting-temperature fields. A thermocouple array was mounted on the rake surface of the tool. Using this functionalized tool, we can discuss in depth the temperature influence on the workpieces. Additionally, dynamic control of the machining based on temperature can be achieved.

|

|

Precision Machining of Hard-Brittle Material

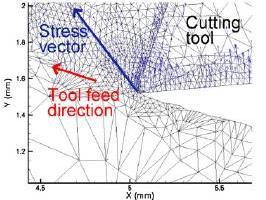

Tungsten alloys and engineering ceramics are very hard and fragile, and thus classified as hard-brittle materials. We have been developing precise machining methods of difficult-to-cut materials, specifically of hard-brittle materials. Inspired by innovative ideas and principles, we propose new machining methods and validate them by intensive experiments. For example, we are investigating cutting-burnishing of tungsten alloys and high-temperature cutting of ceramics.

|

|

Evaluation of a Regenerated Cartilage Based on its Viscoelasticity

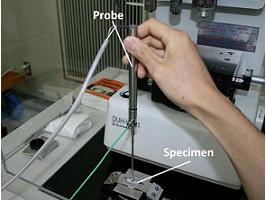

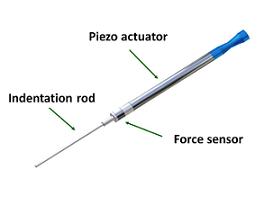

In recent years, implantation of a regenerated cartilage has been applied to the treatment of osteoarthritis. However, an evaluation method for the implanted cartilage after the surgery has not been established. In this research, a probe-shaped diagnostic instrument has been developed to measure the viscoelasticity of the implanted cartilage so as to quantitatively evaluate the recovery status. The shape of the instrument would enable minimally invasive diagnosis, which would lead to earlier clinical applications of the developed instrument.

|

|